Compact. Precise. Cleaner parts.

MVJ-1 — MQL for high-precision shops

Keep parts clean, extend tool life, and ditch the flood. MVJ-1 delivers repeatable, low volume lubrication tailored for various machining operations

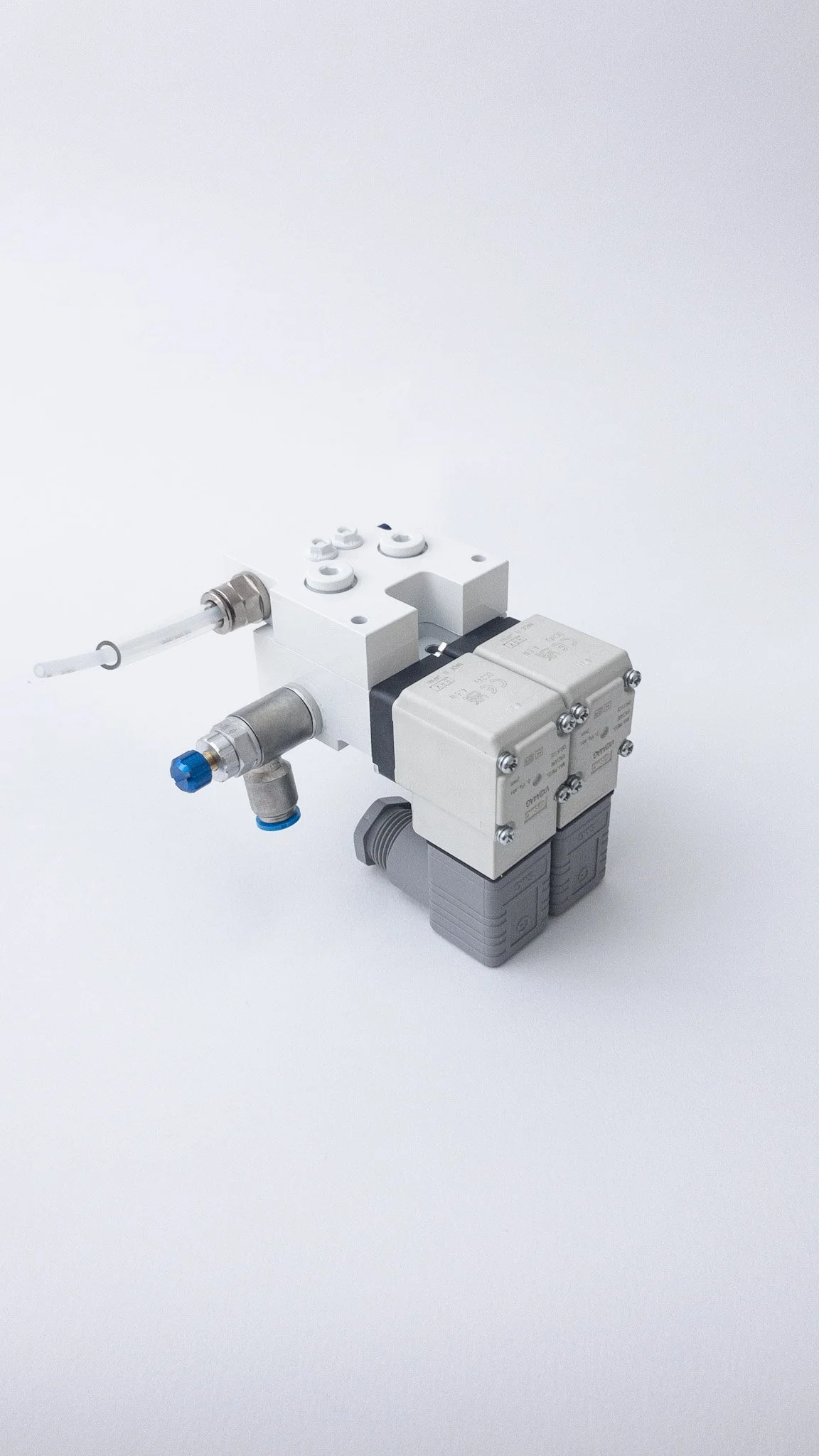

MVJ-1 Modular MQL System — Product Description

The MVJ-1 is a compact, workshop-friendly MQL (Minimum Quantity Lubrication) system built for micromachining and precision turning where control, cleanliness, and flexibility matter. The MVJ-1 system starts with a 1-liter reservoir and a single nozzle control valve, then grows with your needs: add reservoir modules and valve blocks as your needs expands, without redoing piping or control logic.

Unlike fixed single-point units, the MVJ-1’s modular design which enables you to expand the 1 liter reservoir capacity to your needs — simply bolt on additional reservoir modules to increase capacity where you want it (near the machine or centrally for a cell). Each module locks together with leak-proof quick-connect fittings and includes filtration and optional level sensing so the system stays reliable as you scale.

Equally important is the modular nozzle valve block configuration which enables you to have independently controlled MQL nozzles. The MVJ-1 uses plug-in valve blocks: each block contains precision metering valves and individual on/off control so every nozzle can be tuned for flow, pulse timing, or disabled entirely. Stack additional valve blocks when you add tools or machines — less waste, better finishes, longer tool life.

Key features

Base 1 L reservoir with tool-less expansion modules — scale capacity without downtime.

Modular nozzle valve blocks with independent control per nozzle — precise, targeted lubrication.

Precision metering and pulse control for true MQL performance (fine droplets, repeatable delivery).

Quick-connect fluid lines and filter cartridges for fast maintenance..

Simple mounting hardware for retrofit to lathes, VMCs, Swiss machines, and multi-spindle setups.

Shop benefits (what you’ll actually notice)

Cleaner chips and workspaces compared to flood coolant — less cleanup and lower disposal costs.

Reduced lubricant consumption with precise delivery only where needed.

Easier process tuning: independently controlled nozzles let you optimize each tool and operation.

Faster scale-up: add reservoir or valve modules as shop demand grows — no new base unit required.

Typical applications

Swiss turning and micro-turning where small droplets and tight control are required.

High-speed micro-milling and drilling on VMCs.

Job shops and production cells that need to add MQL points over time.

Options

Expansion reservoir modules (stackable), additional valve blocks, nozzle kits (various orifice sizes), and custom solutions.

The MVJ-1 gives you the precision of modern MQL with the flexibility of a modular system — start small with a 1-liter base and grow exactly where you need it, while giving each nozzle the individual control your processes demand.

Installation & compatibility

Mounting: Small footprint allows mounting to machine cabinet or a nearby bracket. Provide 24 VDC power and an on/off control line for cycle synchronization.

Plumbing: The system uses a coaxial tube to deliver compressed air & oil to the nozzle. This ensures a clean & easy installation.

Control: Use the machine M code output or PLC to provide run/stop. Optional analog control for flow adjustment from the control panel.

Recommended for: Swiss lathes, micromachining VMC, medical/dental micro-machining, R&D labs.

Compatible fluids: The system has been tested in production environments with several different types of cooling fluids. These include:

Neat machining oils

Ester oils

Water miscible, mineral oil based cooling solutions

Synthetic cooling fluids

Ethanol based machining fluids & Pure ethanol

Why MVJ-1

MVJ-1 is an engineered MQL (Minimum Quantity Lubrication) system built for precision work. It gives you tight, repeatable micro-lubraction without the mess or disposal costs of flood coolant.

Cut costs: drastically less lubricant used, lower cleanup & disposal expense.

Cleaner parts: minimal residue means easier inspection and faster handling.

Longer tool life: precise micro-dosing reduces heat and wear.

Fast ROI: consumables drop, cleanup time shrinks.

Key Features

Precision micro-lubraction System— engineered to deliver consistent, and reliable lubrication.

Adjustable pressure & flow control— dial in what your process needs, from a whisper to a steady mist.

Compact & Easy to install— mounts easily on or beside your machine.

Simple CNC integration — Easily integrates in to most common CNC machine tool controls. Simple 24 VDC control signal is all that is needed. (Other options on request)

Low maintenance — easy to service filters and reservoir; built for shop life.